Directional Pads – observations for fitting

29 Sep 2021

With constant demand for improvement in all aspects of performance, vehicle manufacturers have designed brake pads for numerous applications that must be mounted directionally. As such after-market brake specialists such as Apec Braking have followed suit, offering replacement pads that perform in line with the original equipment.

Directional brake pads differ from a traditional brake pad in their form, so measures need to be taken by fitters and technicians in order to minimise fitting issues and the knock on effects to that vehicle’s performance and to the customer. It is the garages that pay the ultimate penalty when parts are fitted incorrectly, and as such education is key for independent garages looking to minimise customer dissatisfaction. As the saying goes “Do it right, or do it twice.”

Initially therefore it’s imperative that installers understand how directional brake pads function and get to grips with the issues they have been designed to prevent.

What issues do directional pads alleviate?

As vehicles grow increasingly larger and heavier with the requirement of standardised safety features, car manufactures have a tough time eliminating these foibles, so much so that the braking system on a modern vehicle can take 3 years of research and development to get right. The focus of much research and development centres on the manufacturer’s requirement to reduce N.V.H (noise, vibration and harshness).

Interestingly every single automobile on the road will have gone through unique and extensive test- ing in order to develop a braking system particular to that vehicle; one that ensures optimal braking efficiency in addition to focused technology such as directional pads, that enhance the driver experience from behind the wheel.

Most would assume that advancements such as directional pads offer an improvement in braking performance, the thinking being that a pad designed to operate when a brake disc is rotating in a certain direction must improve thermal efficiency, or in layman’s terms, reduce the build up and retention of heat, a killer of braking performance.

The fact is however that directional pads do not necessarily improve a brake pad or disc’s ability to expel excess heat, they in fact serve two main functions; the reduction of vibration or chatter, and the elimination of brake squeal or noise.

Directional brake pads – what should technicians be aware of

There is not a singular or conventional way a directional pad operates as manufacturers have various methods for solving the problems described above. There are therefore numerous methods employed, all of which technicians need to be aware of when deciphering how a directional brake pad should be correctly fitted.

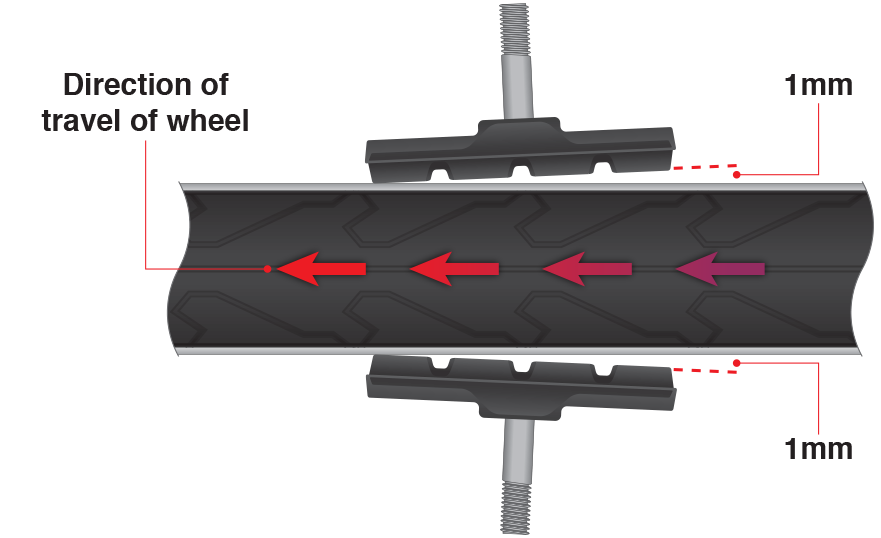

Chamfer

Standard brake pads can be “pulled’ by the brake disc on application, which can lead to damage as well as poor braking performance and uneven wear. Chamfers offer a transitional edge be- tween two vertices of an object and will likely be present on the leading edge of a brake pad, or on both edges of the pad. In general chamfers are angled anywhere up to 45 degrees and serve three main purposes; to induce even pad wear, to prevent the leading edge of the brake pad lifting and being pulled away by the brake disc and to reduce noise.

When installing brake pads with chamfers fitters need to keep en eye out for the angular edge of the friction material. If there is no arrow on the back of the pad and there is only one chamfer, then that chamfer needs to be presented at the leading edge where the pad first contacts the brake disc.

Shims

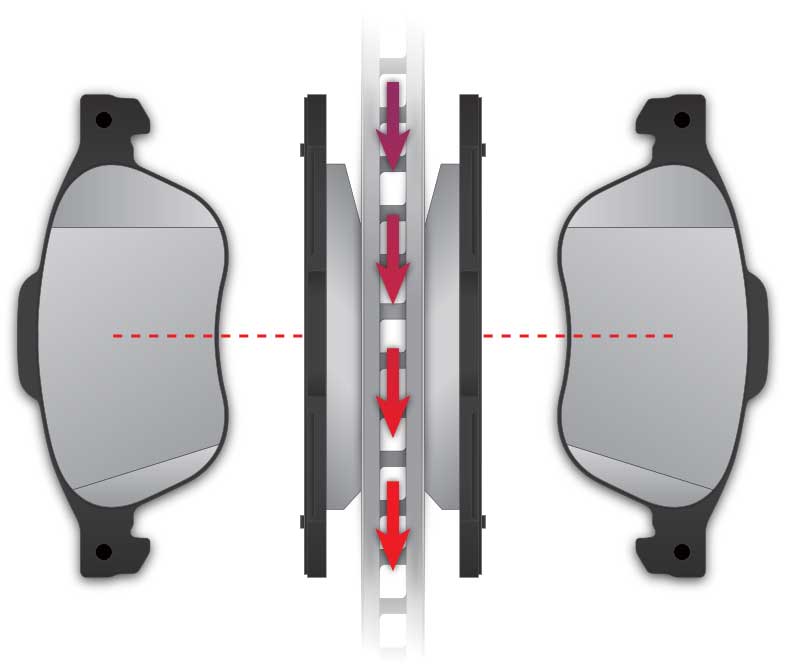

Almost all brake squeal is caused by oscillation between pads, caliper and discs. Through rigorous research and development, Apec Braking is able to manufacture shims that are fixed or clip-on to the rear of each brake pad, helping to locate it correctly within the caliper.

Brake shims prevent and reduce the transmission and amplitude of vibrational forces or brake chatter, which is achieved with dampening material bonded to the pad assembly. Shims also add mass to the brake system, dampening vibration in the pad and calliper. Finally shims can also act as a thermal barrier to ensure even temperatures across the pad, which translates into more consistent braking.

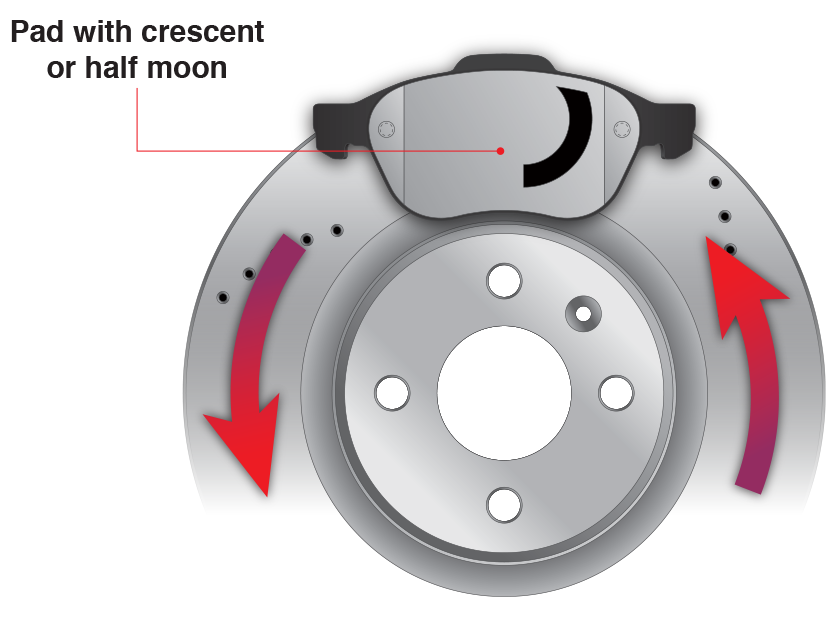

Shims featuring a half moon or crescent cut-out

Fitters need to be aware that some shims may have a crescent or half moon cut out present, which allows the piston to push the brake pad at a desired angle, reducing noise and creating more unified and even pad wear. The below example of an old fashion push bike’s braking system simplifies the physics here, with the location of the half moon or crescent cut out ensuring the piston makes contact with the pad and forces it against the wheel (or brake disc) at a desired angle, halting brake chatter.

The half moon can be accompanied by a directional arrow, however if this is not present the cut out will appear on the leading edge of the pad. It is imperative that this crescent/cut-out runs horizontally across the brake disc, and should be located on the leading edge to ensure even pad wear and the correct distribution of force across the brake pad surface. This reduces pad oscillation and thus prevents noise.

If this type of pad is fitted in the opposing direction then you are highly likely to experience noise as the leading edge will contact the disc first, causing chatter, heard by the fitter or customer as a high pitch squeal.

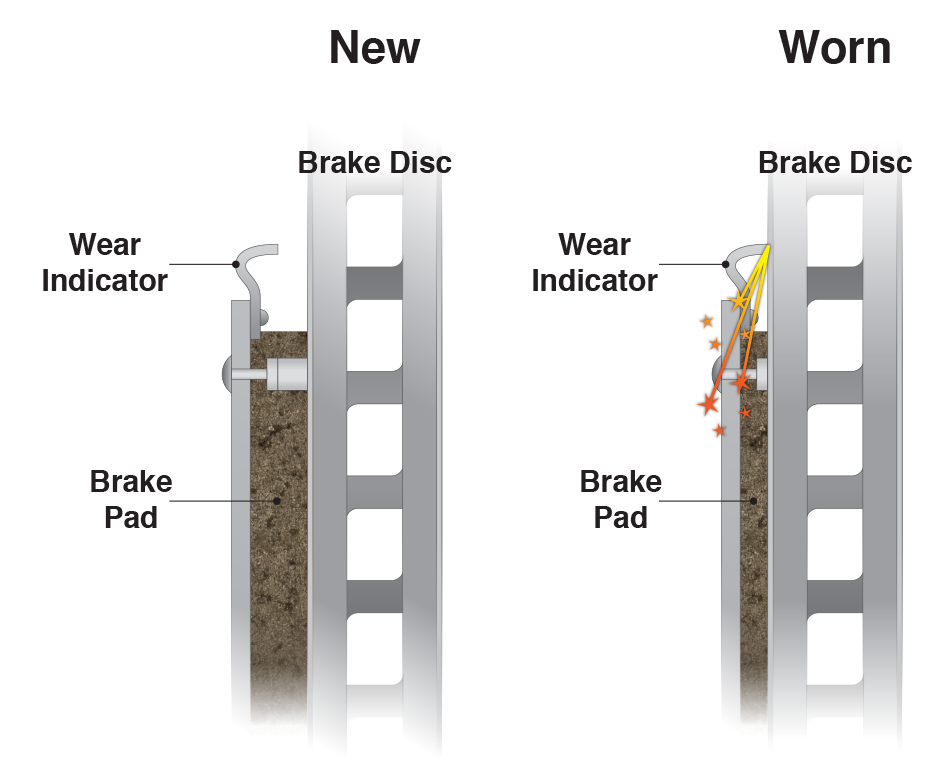

Directional/wear indicators

Many brake pads will feature wear indicators, these can be sophisticated and run electronically so best practice is to look at how the previous indicator was “plugged-in”. It is likely that a directional pad featuring an electronic indicator will only fit correctly in one direction (inspect the length and angle of cables).

More commonly brake pads feature a simple metal hook that “screeches’ on contact with the brake disc. It should feature on the leading edge (so the indicator makes contact with the disc before the pad). If these pads are installed the wrong way round the indicator will not sound correctly and thus customers may increase the likelihood of damaging the brake disc as they run their pads below the minimum threshold.

What happens if directional pads are fitted incorrectly?

If a directional brake pad is fitted facing the wrong direction there is less chance of optimal braking efficiency. That will in all likelihood lead to pads squealing under application.

There is clearly a right way and a wrong way to fit directional pads, and it is ultimately the technician or garage that will suffer as a result, therefore it makes perfect sense for technicians to take a few minutes to properly inspect both the pads being removed as well as the new pads intended for fitting for clues as to their orientation. Is there a Technical Bulletin regarding this part number? If it’s the first time you have seen the car then identify how the previous pads were fitted, reverse engineering the process.

If none of these steps clarify how a pad should be fitted technicians are encouraged to look for chamfers, directional grooves, clip on shims, half crescent cut -outs and wear indicators. If none of these clues are present garages can call Apec’s technical support team (01454 324644), who will be able to identify one of Apec’s 74 directional pad part numbers and advise of the correct fitting procedure first time round.

Doing so will guarantee pads are installed correctly, which means your customer won’t be subject to vibration, squeal or poor or uneven wear.

Wrongly fitted parts lead to unhappy customers, the loss of a service bay and a technician who has to first diagnose the issue, and subsequently fix it. None of which are the ingredients for good business or customer satisfaction.

Apec Braking are always on hand to support the thousands of garages and technicians we work alongside, so if in doubt please get in touch; we’d be delighted to hear from you.

TECHMATE is here to make your life easier

When you need to know more about braking with Apec, ask TECHMATE. Call Graeme, Matt or Siti on 01454 285054 or email [email protected]