Corrosion and how it affects braking systems

29 Sep 2021

Corrosion is a natural process that deteriorates metal or its properties because of a reaction with the environment. The corrosion that we are most familiar with is the formation of rust on the surface of metals when they are exposed to Oxygen and moisture. Rust is Hydrated Iron (III) Oxide which is the by-pduct produced by this reaction. Scientifically this is an electrochemical process which returns metals to a thermodynamic state.

Corrosion is an extremely costly and dangerous problem. If not prevented it can lead to the collapse of buildings and bridges. Medically it could be fatal, as blood poisoning could occur from corroded metallic implants. In automotive applications corrosion is aggressive due to high pollution levels and exposure to de-icing salts. The Society of Automotive Engineers (S.A.E) estimates the corrosion rate to be in a similar range to marine environments (8.5 µm/year). In braking, several components are manufactured from cast iron. The benefits of using cast iron range from its high resistance to distortion, its durability when subjected to different type of forces and produces great friction coefficients. However, the disadvantage is that cast iron is highly anodic (corrosive). Which is quite ironic as most consumers tend to blame the quality of metal for corrosion not realising that the high content of iron in brake discs is essential for safe and efficient braking.

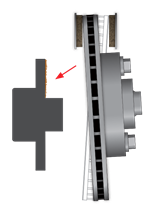

In areas of high humidity, brake discs will corrode at a faster rate than in arid areas. This issue is easily resolved by applying the brakes when driving which will clear the surface corrosion. Apec Braking go one step further to protect the brake disc against corrosion by matching the OE design of coating disc edges and the hub with a black coating for effective protection and long-lasting smart appearance. There is no coating on the friction surface to contaminate the pads and reduce their efficiency. However, corrosion does become an issue when the brake discs are left stationary for a long period of time in an area that has more than 80% of relative humidity. Corrosion on the surface of the brake disc can lead to an increase in NVH (noise, vibration and harshness) and reduce braking efficiency. In more extreme cases this can lead to corrosion adhesion between the brake disc and pad that can cause severe damage.

In areas of high humidity, brake discs will corrode at a faster rate than in arid areas. This issue is easily resolved by applying the brakes when driving which will clear the surface corrosion. Apec Braking go one step further to protect the brake disc against corrosion by matching the OE design of coating disc edges and the hub with a black coating for effective protection and long-lasting smart appearance. There is no coating on the friction surface to contaminate the pads and reduce their efficiency. However, corrosion does become an issue when the brake discs are left stationary for a long period of time in an area that has more than 80% of relative humidity. Corrosion on the surface of the brake disc can lead to an increase in NVH (noise, vibration and harshness) and reduce braking efficiency. In more extreme cases this can lead to corrosion adhesion between the brake disc and pad that can cause severe damage.

Brake pads are also not exempt from corrosion. Corroded backing plates can cause delamination of the friction material that could lead to an increase in NVH, the complete detachment of the friction material from the backing plate, loss of braking efficiency and stability. To protect brake pads against corrosion, Apec Braking coats the backing plate with an anti-corrosion layer. If removed this could make the backing plate more susceptible to corrosion.

Brake pads are also not exempt from corrosion. Corroded backing plates can cause delamination of the friction material that could lead to an increase in NVH, the complete detachment of the friction material from the backing plate, loss of braking efficiency and stability. To protect brake pads against corrosion, Apec Braking coats the backing plate with an anti-corrosion layer. If removed this could make the backing plate more susceptible to corrosion.

Components surrounding the discs and pads are also susceptible to corrosion. To ensure the optimum performance, the components must be treated to combat the effects of corrosion. Free movement is essential for the brakes to be effective, therefore contact points that are susceptible to corrosion must be lubricated with the correct lubricant to facilitate free movement and protect the area. The lubricant used must be able to withstand high temperatures and must be completely metal free to avoid galvanic corrosion that will restrict movement. Apec Braking provide a petroleum-based lubricant that effectively protects surfaces as well as being fully compatible with ABS and ESP braking systems.

Components surrounding the discs and pads are also susceptible to corrosion. To ensure the optimum performance, the components must be treated to combat the effects of corrosion. Free movement is essential for the brakes to be effective, therefore contact points that are susceptible to corrosion must be lubricated with the correct lubricant to facilitate free movement and protect the area. The lubricant used must be able to withstand high temperatures and must be completely metal free to avoid galvanic corrosion that will restrict movement. Apec Braking provide a petroleum-based lubricant that effectively protects surfaces as well as being fully compatible with ABS and ESP braking systems.

Corrosion is further accelerated by certain methods and detergents used to clean the surrounding brake areas.

Corrosion is further accelerated by certain methods and detergents used to clean the surrounding brake areas.  Pressure washing can introduce moisture and acidic detergents to tight crevices between the brake disc and hub and can cause corrosion to build up and cause misalignment of the disc that will lead to an increase in NVH.

Pressure washing can introduce moisture and acidic detergents to tight crevices between the brake disc and hub and can cause corrosion to build up and cause misalignment of the disc that will lead to an increase in NVH.

Although we are unable to change the habits of a consumer there are steps that can be taken to minimise the formation of corrosion. At the point of installation, cleaning the hub surface and protecting with a suitable lubricant will prevent corrosion build up.

Caliper slider boots can become detached from the force of pressure washers, leading to the introduction of moisture in the cavity – in turn leading to corrosion build up inhibiting movement. It is imperative that they are removed, inspected, cleaned or replaced and lubricated with a hydrophobic lubricant, compatible with the rubber boots, that will repel moisture.

There are many other issues that can arise from corrosion that can affect braking, so if you ever have any questions please feel free to contact our technical team on 01174 288100.

Apec Braking is proud to provide you with technical information to support the quality of its products and to uphold its “Full Spec. Full Stop.” promise to customers.